Despite what you may have heard, China is still the #1 place to get your product manufactured—whatever product you have in mind.

But, how do you find a manufacturer in China?

Easy. Basically search on Alibaba, along with one or two other things.

But how do find the manufacturer that’s right for

you?

It’s hard. Really hard. Unless you know the right technique.

I’ll point you in the direction of that technique. And, it may be a cliche, but the key is to

work

smarter, not harder.

CONTENTS

WHY CHINA?

“This coffee shop is successful because they never take one day off throughout the entire year, not at Christmas or even Chinese New year,” said the curator. “Business is always good because people know the coffee is being served 365 days a year without exception.”

Consistency,

predictability and a

fierce work ethic infuse every Chinese business at whatever scale they operate, wherever they operate.

These qualities are most on display, though, in China’s manufacturing system and are key to understanding China’s rapid industrial transformation.

Most importantly, they are qualities to keep in mind as competing industrial centers — notably in India and Southeast Asia — offering ‘cheaper’ labor come onstream.

A China-based supplier still provides unsurpassed value for money and will continue to do so well into the future.

High End vs Low End (and in-between)

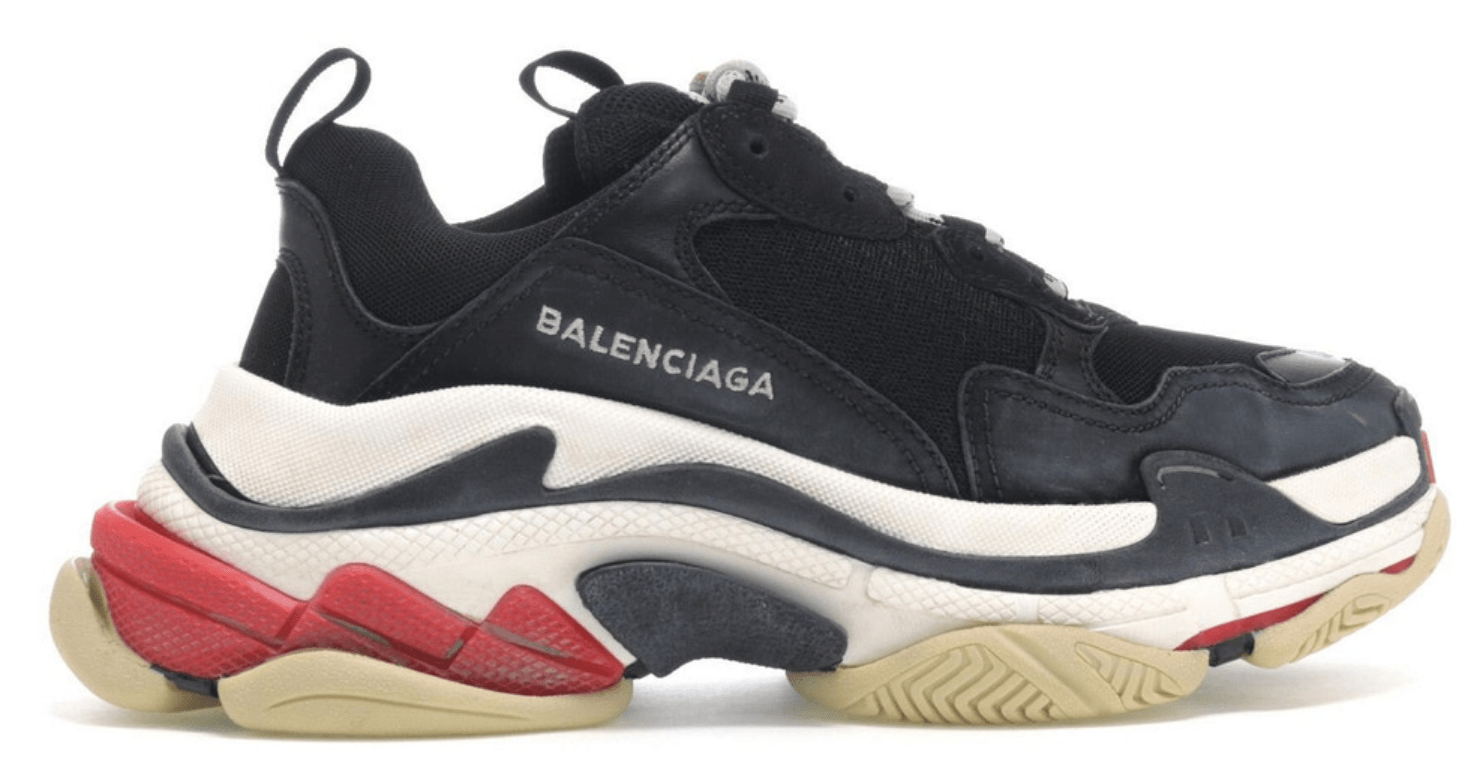

China has a reputation as the source for dollar store quality items.

The truth: many of the world’s luxury brands are made in China including Prada, Miu Miu,

Balenciaga, Burberry, Armani, Dolce & Gabbana, Louis Vuitton, Coach, Nike, Adidas, Patagonia.

And that’s to name a few.

A number of manufacturing levels are available in China.

If you are looking for dollar item quality, you will find plenty. But if you are looking for premium quality, it’s certainly available. You’ll need to pay more though.

Quality is always depending upon the budget that you, the buyer, is willing to outlay.

The difference between high end and low end is the degree of precision brought to the manufacturing process.

In my experience with TUMI & Coach production, to name two high end brands I’ve worked with, the bar is extremely high—the level of quality is off-the-charts.

It largely comes down to bag sizing tolerances which must be kept within 3mm.

What you are paying for in achieving those tolerances is China’s

- highly optimized factory processes

- highly skilled workers

That’s the China advantage.

Mature Infrastructure

China’s transportation networks are second to none.

In the past decade, the high-speed rail system has massively increased the ease of getting around the country.

As of 2019 the total length of China’s HSR was 35,000 km or 2/3 of the world’s total HSR track.

More than 50% of the world’s 4G cell coverage is in China with 5G networks also in rapid development.

China is also the world's largest mobile payment market, and handled more than 500 billion mobile payment transactions in 2018 alone.

7 out of the top 10 global container ports in the world are in China, the biggest one being Shanghai.

World leading infrastructure and communications has created the world’s best supply chain integration by a long way.

Supply Chain Networking

This sophisticated infrastructure enables thousands of small towns you have never heard of to produce an enormous range of goods, both for local consumption and the global market.

- 30% of the world’s guitars is produced in Tangwuzhen, Changle Country, Shandong Province

- 30% of the world’s violins are produced in Huangquiaozhen, Jiangsu Province

- More than 50% of the world’s steel tape is produced in Shangqui, Henan Province

- More than of the world’s lighters are produced in Shandong, Hunan Province

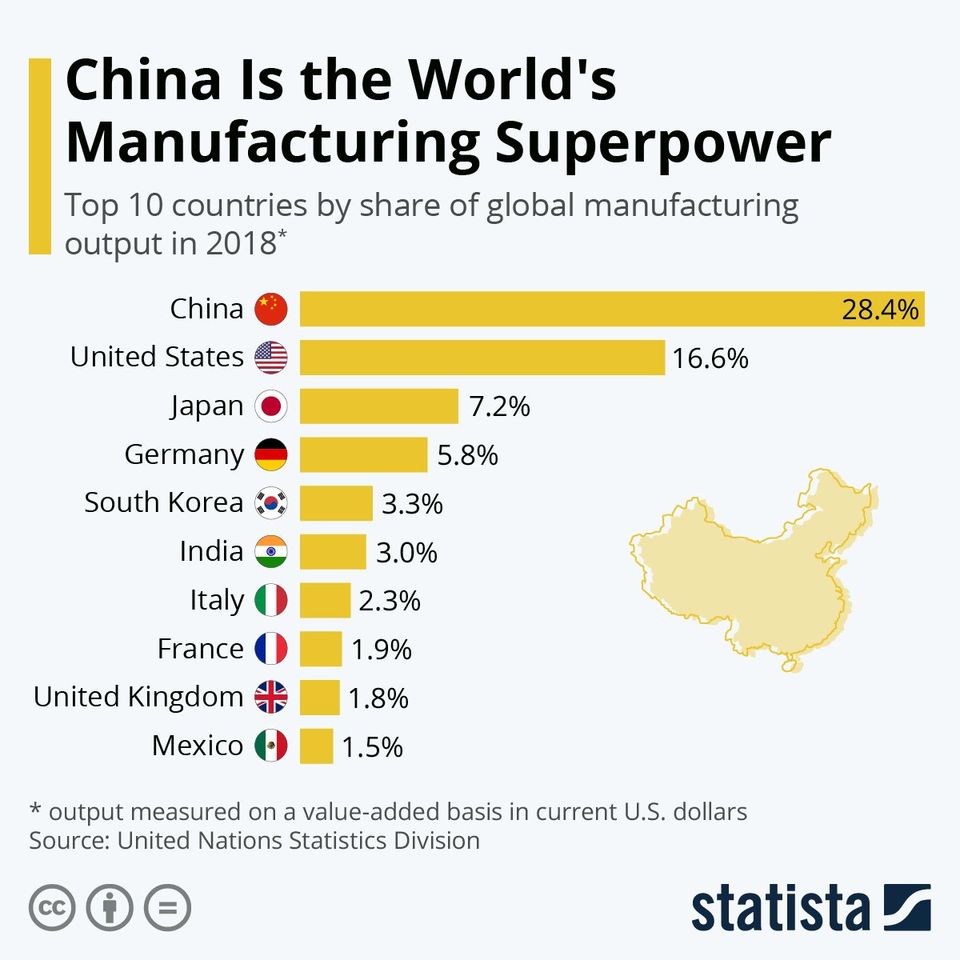

All Industries Are Covered

According to the United Nations industrial taxonomy, there are 666 industrial sectors in all.

China is the one country that produces products in every one of them—a first in human history.

From high end to low end, from military to every day household items, China’s suppliers manufacture in every sector.

So, Why China?

Because you get highly skilled workers able to produce top quality goods to the most exacting tolerances, including handiwork. That’s why.

Moreover, China’s infrastructure, communications and complete supply chain integration covering every industrial sector makes in the no brainer manufacturer for the world.

The only problem is how do you negotiate your way through this world to find the manufacturer right for you?

Despite the sheer abundance of manufacturing excellence, how on earth do you find a manufacturer in China?

TRADE FAIRS

Trade fairs have long been the traditional, tried and true way to find a manufacturer, and will remain an important business tool in that regard.

Trade fairs are a main method I use to explore new materials and manufacturers.

Trade fairs are an efficient way to find the trustworthy partner

IF you have the right product and industry knowledge, however—the more of both you have, the better.

You’ll get product, material, and often manufacturing process details, as well as the all-important MOQ of course.

If you know what you are looking for, you can fast screen vendors and make a short list of possible partners.

Apart from this you will often discover inspiration or frank truths from the conversations you have. I always learn a lot from talking with manufacturers.

A very important point: plan your schedule and book a hotel well in advance of a trade fair, since the bigger fairs attract huge numbers of buyers from all over the world.

The following section details the most important trade fairs in the Fashion and Outdoor Accessory

Here is some important trade show in the Fashion and Outdoor Accessory sectors you shouldn’t miss.

Trade Fairs Are Great — But...

...you need to have the right knowledge to make best use of them.

Consider using a

full-service sourcing agent, since this takes the risk out of every aspect of finding a manufacturer in china, getting your products made to order, delivered on time and your intellectual property protected.

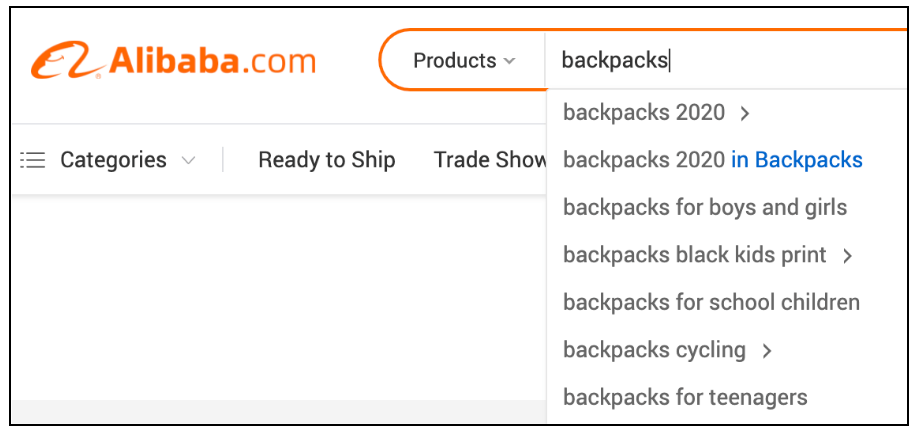

USING ALIBABA TO FIND A MANUFACTURER IN CHINA

Using one of the many trade platforms can replace trade fairs completely in your search for the right china manufacturer.

The main platforms are:

Their functions are quite similar. But you are hard put to go past Alibaba—it’s the best site because it’s:

- the biggest market place, and

- the place to find your ideal manufacturer.

But,

you need to know how to use it.

The simple process for searching for a manufacturer on

Alibaba goes as follows.

You pop your keyword into the search box and hit ‘Enter’. Or if one of the auto suggests is close to what you want, then just click on that.

If one of the auto suggests is close but not specific enough, you can add your own qualifying keywords to it, such as preferred types of material or something like that.

Whatever the case you’ll find that in the blink of an eye you’ll have in excess of 100 suppliers to consider.

Manufacturers — No Resellers or Trading Companies

The most important tip I can give you is make sure you are dealing just with manufacturers.

Adding the golden manufacturer filter will reduce the list to maybe around 50, which certainly helps. But that’s still a hell of a lot of suppliers and many hours of work ahead of you as you sift and painstakingly create your shortlist.

Making the (Tinder) Shortlist

The process that follows is a lot like what you might experience on Tinder. And just like Tinder the trick is to go beyond appearances to the very essence of who you are dealing with. But first things first.

The manufacturer’s profile photo allows you to swipe right or left.

After 10 minutes you’ll have reduced the list to maybe around 20. And then the really hard work begins, the process of finding out which one will be the best matchup for you.

If you were to allocate a score from 1-10 for each criterion, you’ll find nearly all of the china manufacturers on your shortlist score really high.

But, of course, you haven’t yet met in person, let alone been on a first, second, or third date.

The devil in this business of teaming up with the right manufacturer is absolutely in the details.

Here’s how to find the right one in half the time.

HERE’S HOW YOU FIND A MANUFACTURER IN CHINA—FAST

Speeding up the process means taking a different approach. I’ll now show you how to use Alibaba’s power in a different way.

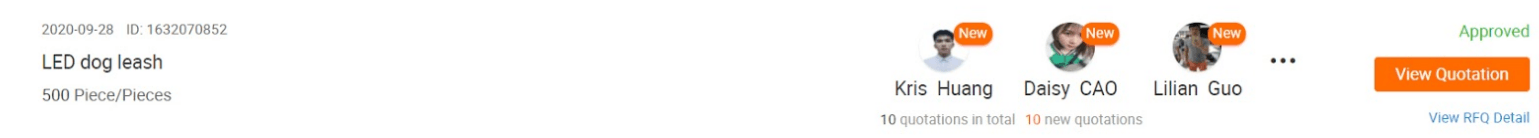

Send a Request for Quote (RFQ)

instead of carrying out a keyword search, send a request for a quote, or RFQ.

The RFQ is a powerful tool, which enables buyers to send the request to the factory.

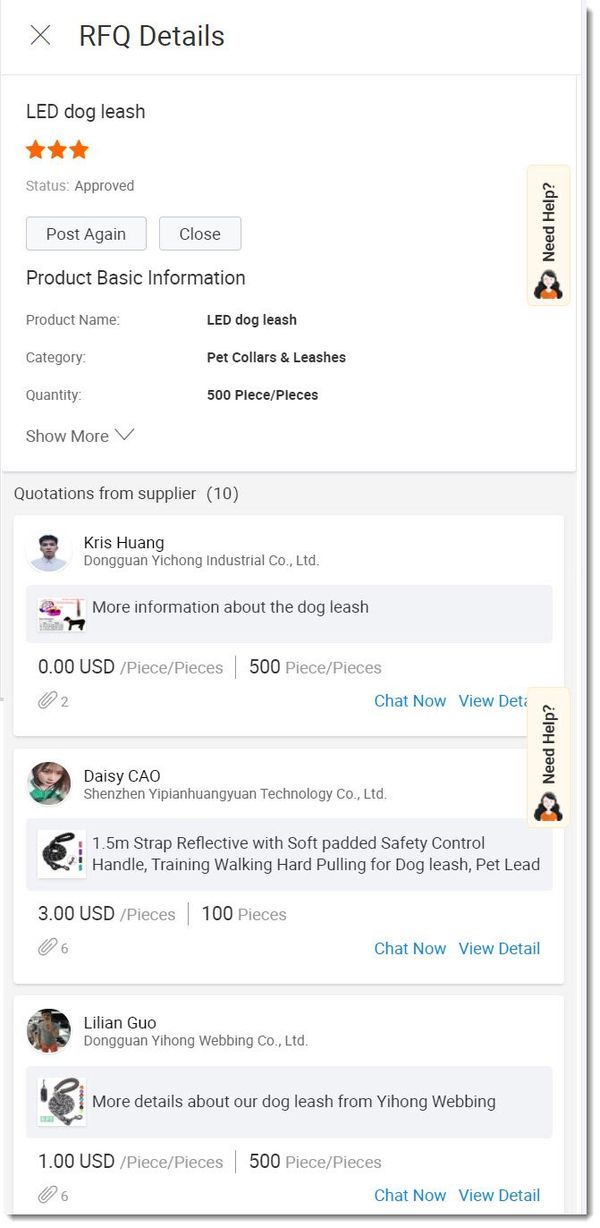

The RFQ screen appears like this:

In each RFQ, you will get 10 factory price quotes.

It’s important that you include as much detail as you can.

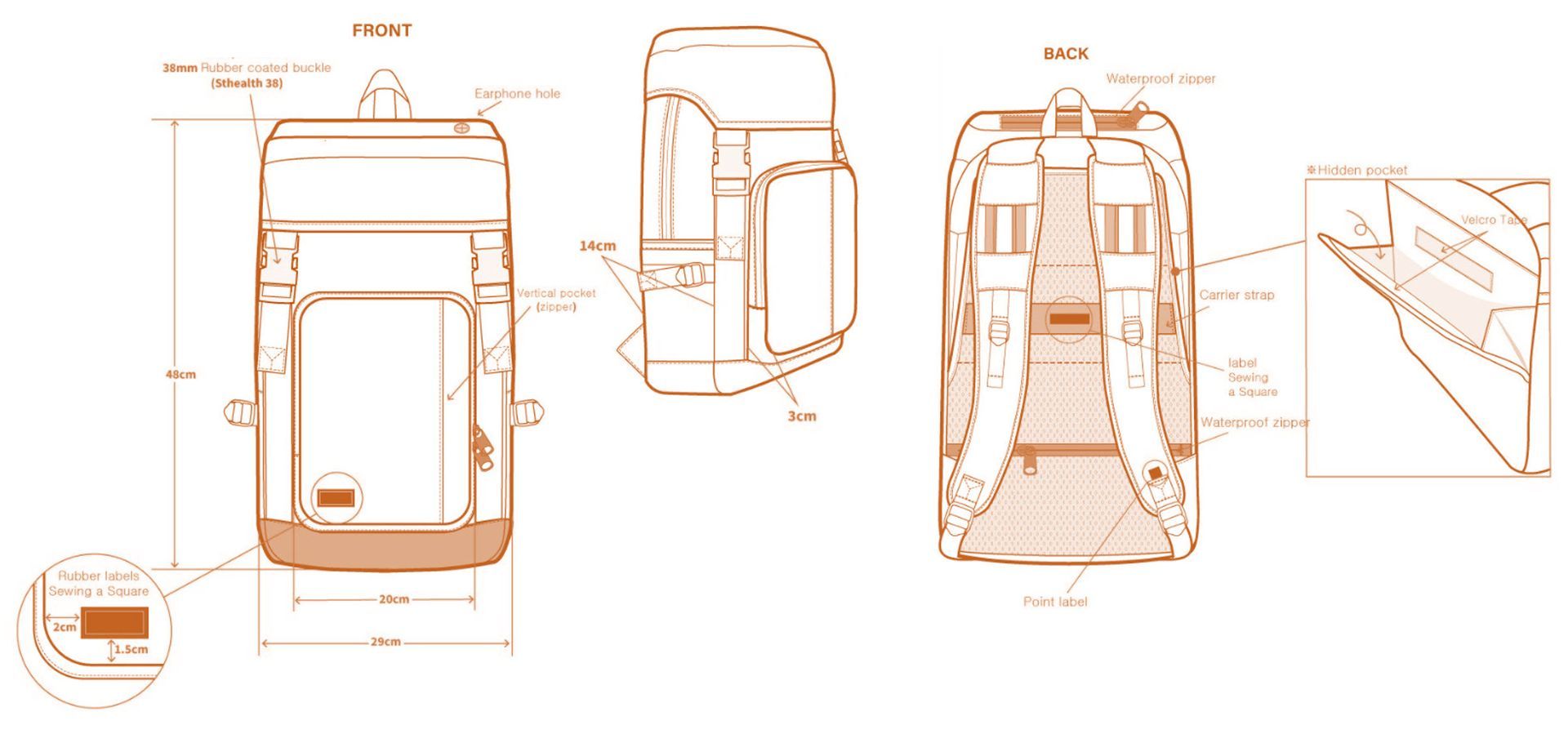

Details, Details, Details

Avoid describing your product in general terms.

The more details you include, the easier you make it for the manufacturing personnel to address your needs. Plus you also show your professionalism, that you are a serious customer with whom they can do business.

Get razor-specific and focus in exactly as much detail as you can. Narrow it down.

For example, if you are looking for a mountain backpack with an aluminum frame supporting system, don’t just tell the factory you want to develop a ‘backpack’.

There are so many different types of backpack design that exist within the backpack category with accordingly different functions.

Take a daily backpack (Jansport style) for example.

This is the most basic style of backpack, with simple construction and simple back panel design.

The first thing I’ll do is check a potential backpack factory’s product line to see if they have a similar style product as the one I’m looking for.

I’ll make sure the factory uses a

synchronous stitching machine, which makes the bottom stitching appear exactly the same as the top stitching. I would include all this in the basic request.

If I was looking for a fashion backpack, then I would specify

PU or

leather, both of which require a factory to be proficient in

glue and edge painting processes.

But an everyday backpack or mountain backpack was my target product, I would specify polyester or NY fabric, which requires a different functional sewing process.

If I was interested in sports backpacks, with a focus on waterproofing, then I would specify those aspects.

All backpacks mentioned are manufactured, as it happens, by four different manufacturers. The

- materials (and therefore that supply chain)

- construction

- production line setup

- technical aspects of production

are all different. Therefore the details of the RFQ will also be different.

Target the Customer

Related to this, you need to understand the type of customer and market that is the focus for a particular manufacturer.

If you are a EU independent designer brand, for example, then a factory that manufactures for Walmart is not the right one.

Manufacturers used to producing huge quantities at a low price per order won’t be familiar with the high end material supply chain—the production line is designed for quantities in the order of 10k+ per style.

Producing a small order of high quality products will not have the same production efficiency under such a setup which will mean inferior production quality at a higher price in the end.

Are They Responsive?

Usually, you will receive a reply within 24 hours. If not, then use the time between the time you sent your RFQ and get a reply as part of your evaluation:

a fast replying manufacturer may be a much better partner than one which is slow to respond, although that will depend on other factors as well.

When you get a reply from factory, read the message carefully, and find out which manufacturers have really digested the details of your request. Those are the ones to start up a conversation with first of all.

After talking to a factory representative you will get a clear idea of their professionalism, and particularly whether they can handle your project.

A major red flag is that if you see that a manufacturer’s representative didn’t read your product request word by word at the beginning. I can guarantee they will also handle your product with the same attitude and then

you will be on the road to hell. I can’t emphasize that enough.

Quality Conversation

Looking for a good factory is same as looking for a good match on Tinder. How you decide if you want to go out with this man/ woman after swiping that image? Talk to them!

The key criterion for finding your dream manufacturer comes down to the quality of people you will be working with.

A manufacturer’s quality is, ultimately, not defined by fancy buildings or efficient machines.

A factory is working with “people”, yes, real people! Therefore, conversation will tell you if they are a good match for you.

Factory Support is More Important Than Factory Size

‘When eating an elephant take one bite at a time’ so the saying goes. Great businesses always start out small and it takes time to grow big. You only get there one bite at a time.

So for a smaller business, your first order should be small. It’s more expensive because you have less buying power to negotiate with a manufacturer.

The answer is find a small manufacturer since they are, structurally, in the same position as you.

They want to grow their business in the same you do, so you can get a higher priority and better support in factory’s schedule.

I understand that large factories with their impressive premises looks persuasive and appealing to you.

However

a big factory usually requests a high MOQ and accompanying sky-high surcharge.

Another point is that they have other bigger customers than you, higher paying customers who will naturally take priority—your production may well be delayed.

It will certainly not be as important for that manufacturer as the larger customer’s production.

Because small factories usually have fewer customers than large factories, you will be top priority for problem solving.

You’ll probably also get a smaller MOQ because the supply chain they work with may also be smaller, those manufacturers in turn also requiring a lower MOQ.

You will get a shorter sample lead time, and better overall price because the factory’s scale is smaller; thus, overheads are also lower.

All of these elements are crucial when it comes to growing your brand.

For instance, one of my customers is a middle size sports brand. I short listed two factories for them to work with: one factory had 1000 workers, the other 200 workers.

After weighing all aspects I decided to contract the smaller factory on behalf of my client.

However, my client was much keener to work with the larger factory—larger appears to be more ‘reliable’.

But when I compared the price and sample quality from both factories for them, they immediately realized the smaller factory was the way to go.

In the course of working with that factory over 5 years, I was able to grow their business from 200 employees to 800 employees.

And I became the only supplier to the brand for their fashion bag category.

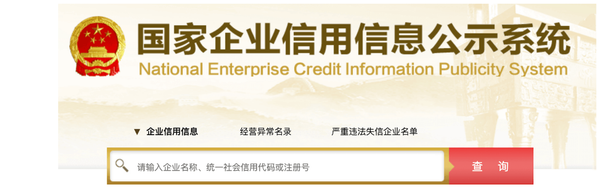

DOCUMENT CHECKING

Careful document examination is absolutely crucial. It is one of the pillars in this whole process. You are on the hunt here for false documentation.

Through this, you learn a company’s registration address, the amount of registered capital, the registration date, and the scope of the business.

It’s very important that you obtain a potential manufacturer’s social credit code.

Once you have this you are able to check if the factory has any sort of a bad record in the

National Enterprise Credit Information Public System database.

The only problem is since the whole process is in Chinese, you may need some help to finish this step.

Another way to verify the factory is to ask the factory to show a bank remittance receipt with their company name on it. If the payer’s name is the same as the registered company’s name, then it’s a real company because the bank will verify each payment resource with the company accountant as a standard money laundering and fraud prevention procedure..

Visit the Factory

There is nothing better than actually visiting a factory. It’s a really important step in the whole process.

If you can’t do that, the next best thing is to hire a 3rd party to carry out a factory visit for you.

Ideally they will send you a detailed report so you will not only know a factory’s export business and production capacity, but also how they manage the quality, material control, manufacturing process, in house inspection, testing, technical machine and protective equipment.

Given the extreme difficulties posed by the Covid 19 pandemic, carrying out this crucial task is extremely difficult without the right partner.

Accord Sourcing has decades of experience with this; it’s our specialty.

Download this factory audit report example so you know the exact information you need to obtain from a potential factory.

Better still, get in touch for a free, no-obligation assessment of how we can help you eliminate the risks and the hassles of DIY.

LATEST DEVELOPMENTS

I’ll update this section periodically when changes occur to any of the procedures or techniques. The biggest change most recently is the new Regional Comprehensive Economic Partnership (RCEP) free trade agreement

RCEP was signed into effect on 15 November, 2020, creating one of the world's largest free-trade zones accounting for 45% of the world's population and approximately 30% of global GDP.

RCEP unification of the

rules of origin will smooth international supply chain functioning by reducing export costs to member states; it also lowers tariffs between member countries.

For example:

- Vietnam will lower import tax from China for fiber/yarn/fabric (HS code # 5208.11.00, #5208.12.00, #5209.11.00, #5209.12.00) from 12% to 1.2%~9% over the next 10 to 20, or 25 years.

- China will cancel import tax for Japan on fiber, yarn, and fabric (HS code # 50-60). Textile and apparel tariffs will also be lowered from a range of 5% - 19% to zero.

- Japan will lower export duty on textile and apparel to other RCEP member (HS Code # 50-63) from 1.9%~ 12.8% to zero.

Since 2008, Chinese suppliers have expanded their production base south of Asia. With lower tariffs between member countries, we will soon see a China + RCEP manufacturing rim.

A way into Asia for European or US brands

If a brand was to have a bag, for example, produced in a RCEP member’s factory or to the point where it could prove that at least 40% originated in a RCEP member country, that brand will receive preferential treatment with the RCEP region, a great boost for any brand wishing to rapidly expand their Asia business.

Accord sources in China, Cambodia and Myanmar, and can customize the most effective supply chain for customers’ needs.

CONCLUSION

So, how do you find a manufacturer in China? Basically 3 ways:

1. Trade Fairs:

will always be around (once we are through this pandemic).

2. The internet: I’ve outlined the RFQ procedure to help you fast-track identifying potential factory partners on the premier sourcing platform, Alibaba.

3. Sourcing Agent:

Find a partner to walk you through the mine-field of finding the right manufacturer.

You’ll avoid the pain of wasted time and wasted money—this is the best way to find a manufacturer hands down! Click here and we’ll show you how.