Why use a sourcing company, instead of dealing direct with the factory?

When you are ready to manufacture your product, should you:

go direct to the manufacturing source

or

partner with a sourcing company?

Factory direct sounds very straight forward; just do a search, find several candidates and go with the most suitable, intuitively you would also think it should be cheaper too.

A sourcing company is an extra layer in the middle - a layer that you might believe you could do without. You might be surprised!

In this article we take a close look at the pros and cons of going direct vs partnering with a sourcing company.

Read on and

find out why going with a sourcing company is often the

best choice!

Contents

Benefits of Going Factory Direct

Downside of going factory direct

The Sourcing Company Advantage

Leverage Price Negotiation—Walmart’s Secret Weapon

BENEFITS OF GOING FACTORY DIRECT

The internet has delivered convenience almost beyond belief when it comes to quickly and easily making business connections.

A quick search will deliver a list of factories with whom you can deal directly to shortlist as candidates.

The question then becomes, which factory is suitable for you to deal direct with?

Communication

There is no denying the benefits of having open, direct lines of communication between a customer—particularly a designer, and a factory.

Often a design is simply not achievable given the cost or technology restraints for a given contract.

When a factory tells you a design is not workable, you can

talk directly with them to find the solution.

Getting unmediated information will also help you to deepen your product knowledge, helping you optimize design in the future.

Become Their Priority

One of the most important factors affecting your relationship and success with a factory is your level of business with them. If the value of your business with them is 30% or greater of a factory’s annual turnover, you will get priority in everything.

Are You Truly Getting Value?

Partnering with a professional sourcing agent may add a small percentage to the unit price, but will add value in so many other ways. If you can work directly with a factory, you may get better unit price—but that’s all you’ll get.

As you will see, the unit price is only part of the

total cost of offshoring sourcing. More on that later.

How to Go Direct

Check out more about this in our complete

article on the subject of going direct.

Very briefly, if you are planning to deal direct, you should look for a company that has a focused merchandise category, or in other words where the products have a longer lifecycle.

Products such as bicycles, lunch boxes, luxury pens, glass water bottles and the like don’t require an updated look every season.

Consistency and stability of product quality is more important than the products requiring seasonal updates, products with a shorter life time.

Your knowledge and experience counts for everything here .

For example, if a factory turns down your request, you need to distinguish whether the rejection means a real problem or they are just giving you an excuse.

If this is an actual problem, do you need to revise your design? What is the nature of the difficulty—exactly—and is there another way around it?

If they are dancing around the issue, how can you get them to keep moving forward with your production? Or should you find a new factory?

These are completely different directions: one forward; the other back.

Making the right choice depends entirely on your professional expertise which enables your brand to work through the details.

Ultimately it is your total experience and expertise which determines if you can enter into a long term production arrangement with a factory or not.

If your expertise is lacking in any area, your difficulties in the years ahead will be compounded.

DOWNSIDE OF DEALING DIRECTLY WITH THE FACTORY

If you go direct then the difficulties you must overcome include:

- Fixed Mindsets

- Wasted Time

- No Backup

Fixed Mindset

In some recent research, I submitted a questionnaire to a group of factories about how they sourced new fabric.

The overwhelming response was that 80% of them sourced with an existing vendor. They

do not visit trade fairs or intend to expand their knowledge about how things are done within their industry.

New product development depends on suppliers knowing the totality of available options.

Point: If a factory is not aware of changes in the industry such as the availability of new materials, then

they severely limit your options.

Having access to a new material could make all the difference by either

- reducing costs or

- increasing the value of a product without increasing costs at a minimum.

The problem with a factory not having broad-based knowledge that translates a designer’s creativity into a workable finished product is that it involves input from varied manufacturing perspectives.

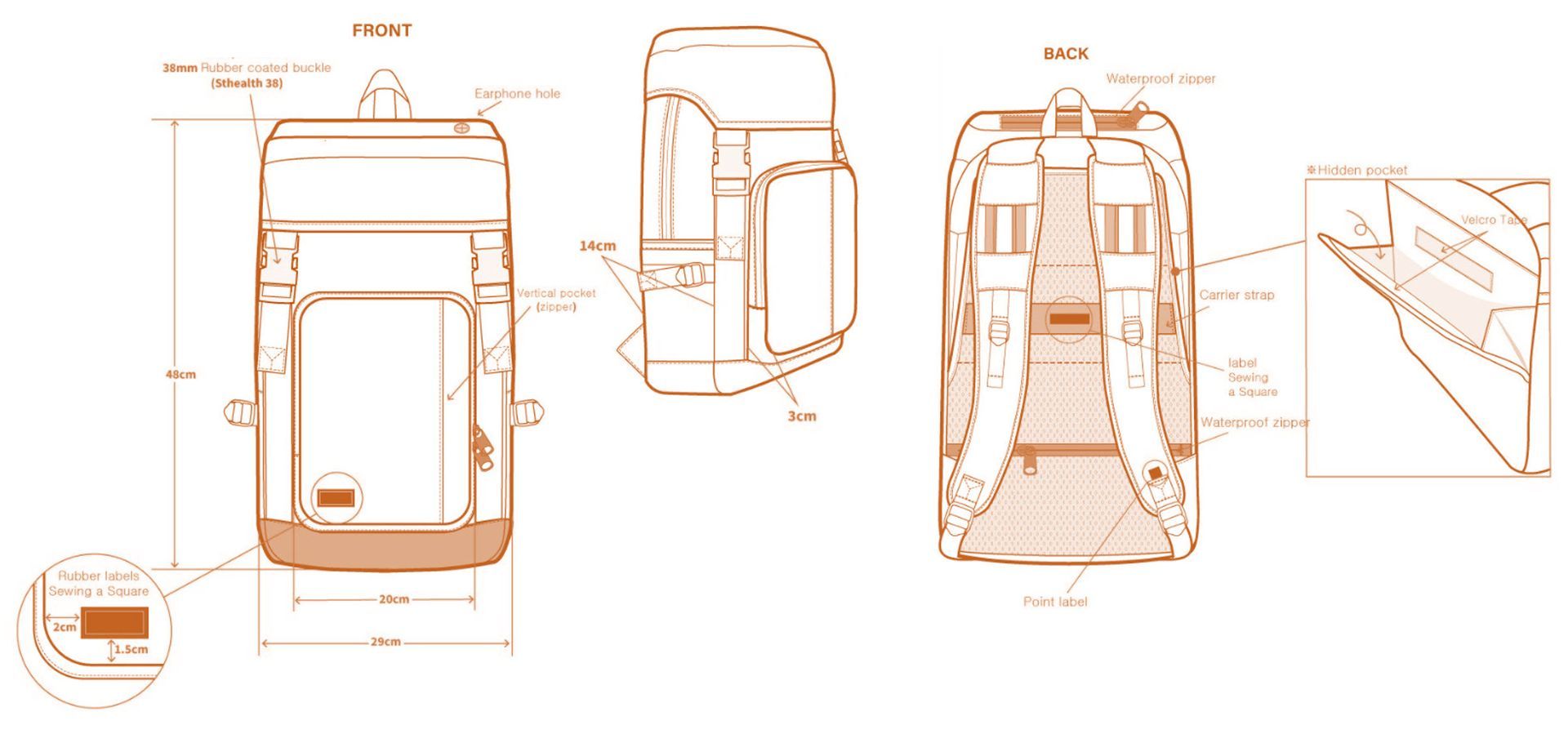

For example, Accord Sourcing developed a daily commute business backpack for a client that wanted a backpack that would allow office workers to keep their clothes neat and crease free while jogging or cycling to work. This was a significant challenge.

The design brief requested a hard case garment box with a folding card.

We created a garment box to hold and protect the suit and shirt, which can be easily taken in and out of the backpack.

The challenge was in finding a material stiff enough for the task and with good elasticity, so that it could be shaped to protect the suit inside and keep it crease free. After discussions on the construction and several mold revisions we found a great solution.

We also needed a folding board to keep the suit crease free. What sounded like a simple item became the most challenging aspect of this project. The board material had to be light, thin, affordable, and have a super smooth edge so it would not snag or damage shirts and suits.

We sourced and tried out different materials, manufacturing the boards by means of different processes including laser cut, CNC cut, and die cut.

None of these met our requirements. The final solution came out of left field – we used an aircraft material supplier to produce and polish boards by hand. And at a reasonable price!

Check out the

case-study for more details.

The main point here is that these factories didn’t know each other, and had not worked together before.

We created bridges from one to the other, without which the project would have failed.

If you cannot connect the factories required to realize your project together, get them working in sync, any creative design remains merely a concept on the paper—it will never end up as a money-making product in the market.

Time Sink

Turning a design graphic into a sample, then turning that sample into a product is enormously time consuming. Most of the time you’ll be solving seemingly unending problems—big and small—that continually come up.

So prepare to spend an inordinate amount of time communicating back and forth with your supplier.

We have one customer who started their brand as a side hustle. The product they developed was a leather and canvas camera messenger bag.

The whole project from designer sketches to sourcing the factory, sourcing the leather, prototyping and the rest consumed 3 years—and they never achieved their objective of a viable production of the messenger bag.

The bottleneck was the lousy quality of the first and second samples.

They eventually made the decision to go with a sourcing company and reached out to us at Accord Sourcing.

We solved all problems inside 6 months and additionally assisted them with sample presentations during the trade show.

No Backup

If your business volume with a particular factory is less than 30% of the total factory turnover then you’ll find there is nearly always a bigger customer ahead of you in the pecking order.

You need to have a backup—a second factory that you can turn to should your primary manufacturer’s production capacity be taken up by a bigger customer.

If you don’t, you have the problem of finding a replacement, a process that

will set you back months, perhaps years.

One factory is not enough

A factory is not a sourcing company; it specializes in, and focuses on, what it does best.

If you are looking to source a number of different products, you need to go through the process of sourcing the right factory for each, with all the time consuming hassle that entails.

THE SOURCING COMPANY ADVANTAGE

You can use the internet to find a factory. But that’s not a straightforward process since you still have to zero-in on exactly the

right factory.

And there are the issues covered above that stand in the way.

The answer is to go with a sourcing company. Here’s a close look at why.

Save Big on Costs

The 2008 financial crisis led Walmart to downsize their in-house sourcing offices in Shenzhen & Shanghai.

They signed a contract with a big sourcing company, Li & Fung, in order to reduce costs incurred in dealing with a large number of importers across their supply chain.

Staff salaries, pensions, local taxes, office rent are all monthly outflows that increase over time, no matter whether business is good or bad.

Outsourcing the buying to a sourcing company transformed the office operational costs into buying costs, which meant Walmart only needed to pay Li & Fung when they purchased a production run.

They also benefited by leveraging the buying power that a big agency, such as Li & Fung, is able to command.

Backup Plans!

Sourcing company staff deal with many factories, and know each of them very well.

They therefore have a list of backup factories on hand should a factory that was expected to take a project turn it down for any reason.

They will also have factory lists from other businesses if they’ve handled some complicated projects in the past.

An example is Accord Sourcing’s recent project in which we developed a camera strap with SD card holder, camera rain cover, and lens cleaning cloth.

This project needed a cross-over amongst three different fashion accessory industries:

- a belt factory

- a jewelry box factory

- an outdoor garment factory

- a cycling pants factory

In total, 35 suppliers were involved in the delivery of this product encompassing a supply chain stretching from Guangdong to Fujian to Jiangsu, a total transportation distance of 1750km.

If you are not able to work across this type of network, or simply don’t have one in place, you are at a huge disadvantage.

At Accord Sourcing, for example, we focus on a number of areas we are good at. Not just one; but also not too many.

We know the industrial niches we deal in very well— fashion accessories and outdoor products, which includes bags, backpacks, mountain backpacks, waterproof backpacks, fashion hand bags, wallets, luggage, and rolling trolleys.

LEVERAGE PRICE NEGOTIATION (WALMART'S SECRET WEAPON)

A sourcing company will negotiate a much better price for you.

A sourcing company has deep roots in the business stemming from their widespread and well-developed network.

And, of course, they already have business with these factories - they combine buying power to get you a much better price.

Walmart’s orders are already large enough to command respect. But when combined with Li&Fung buying power they get the best service regardless of the economic conditions.

It’s a secret weapon that brands of any size can also take advantage of.

Find a Smaller Factory

In our article How to Find a Manufacturer in China, we pointed out the advantages of starting out with a small factory rather than large.

Finding one, though, is not easy, even (especially) online.

The professionals in a sourcing company have their own local and inter-regional networks, removing the effort of finding one along with a guarantee that the factory(ies) you’ll be working with are top notch.

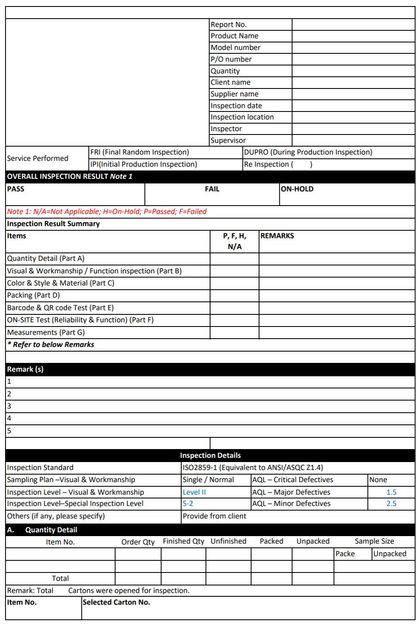

True Quality Control

Stable quality is the most important thing for any brand, so using a 3rd party Quality Control specialist to perform final detailed inspection of production runs at the factory is essential.

Some factories have their own in house QC, but that’s not enough. Factories are blind in certain areas, particularly those that have been in business for a long time.

A third party QC specialist checks the quality standard of a production from an unbiased and clinical point of view.

This is a standard function of a good sourcing company, which conducts thorough inspections during production as well as post-production.

You’ll received a detailed itemized report on numerous aspects of the production process, complete with lots of photos.

Shown below is the first page of the QC Report used by Accord Sourcing. You can download a full copy of the report here,

Less Communication Hassles

Product development is a long journey in which the devil really is in the details.

Nuances of design and production processes are the subject of continual discussion and refinement.

You might think that not having a go-between such as a sourcing company eliminates possible points of confusion; but that’s definitely not the case. We are your advocate working tirelessly on your behalf to have your desired outcomes realized.

To illustrate just a couple of issue from the many issues we see... Should your target production price and initial quantity be very low, how do you persuade a factory to buy into that?

What if the product defect rate exceeds expectations? How do you carefully negotiate your way through that remembering that starting over with another factory is going to blow out your costs.

A sourcing company has

- personnel who speak both the national language and the regional language

- personnel with highly developed skills to persuade a factory to your line of thinking on just about any issue

- more sway with a factory. Either because we have a history of delivering business to the factory, or we are in a position to bring more business to a factory from our other clients, if they do a good job for you

Our team keep the factory aligned with your interests every step of the way.

Same Time Zone

If you’re located in Europe or North America you’ll know the pain that the time difference can cause in dealing with remote factories and suppliers.

The obvious benefit of working with a sourcing company is that they have staff permanently in the local time zone.

A sourcing company provides you with quality representation, face-to-face, in the local time zone.

CONCLUSION

The advantages of working with a sourcing company rather than working directly with a factory are many and varied.

If you are still sitting on the fence, here’s the clincher: make your evaluation all about the

total cost and time to market..

Containing costs is the bedrock on which everything else is constructed. Make a mistake that blows out your costs, and your business life will become miserable, whether you are an entrepreneur or managing a project in-house.

It's not just about saving a few bucks on production. If you can get your product to market months or even years ahead of doing on your own, partnering with a a reliable sourcing partner will allow you to generate a lot more income, a lot sooner.

One piece of advice you’ll often hear in all walks of business is ‘copy what the successful people are doing’.

Walmart is a great example of a company meeting contemporary challenges head-on, taking the fight right up to Amazon for example. The secret to their success is intimately connected to their reliance on their sourcing company partner.

Get in touch with us

at Accord Sourcing for a FREE, no obligation assessment of how you can benefit from the same winning edge.